IAOAI WMS Features

Your business will undergo a remarkable transformation with our warehouse management software, which is renowned for its market-leading capabilities.

book free consultation

Our team has developed systems to enhance every aspect of your operations, enabling you to incorporate the most efficient practices throughout the entire cycle of stocking and shipping processes. What does IAOAI WMS offer? Everything! It is a comprehensive software package specifically tailored to meet the requirements of modern warehouses.

Once you implement our advanced solutions, you will immediately question how you managed without them. The following outlines the numerous features that establish IAOAI WMS as the preferred warehouse management software for leading companies across various industries. Click on each component to learn more about how we can streamline your processes, resulting in significant cost savings and a substantial improvement in your overall business efficiency."

IAOAI WMS Features

Inbound

-

Advanced Receiving Processes

-

Expected Receipts

-

Returns Management

-

Full Quarantine and Release Functionality

Locate & Manage

-

Optimal Put Away Control

-

Replenishment Optimisation

-

Perpetual Inventory Process

-

Extensive QA Traceability

Control & Schedule

-

Full User Authorisation

-

Task and Resource Management

-

Efficiency Reporting

Demand Fulfilment

-

Best Practice Picking Strategies

-

Consignment Management

-

Pallet and Load Assembly

-

Voice Enablement

Outbound

-

Carrier Integration

-

Consignment Management

-

Industry Standard Labelling

-

Advanced Shipment Notifications

Business Intelligence

-

Design & Deploy your own dashboards & analytics

-

Build your own Apps and deploy them across groups and users

-

Custom fields and tables for additional dashboards & analytics use

-

Simple built-in dashboards & analytics

Advanced Receiving Processes

All good warehouse management systems start their advanced inventory management processes right at the very beginning – at goods inwards. But a great WMS gives you the ability to capture all of an item’s attributes before storing it safely and securely in the appropriate area of the warehouse. IAOAI WMS offers this, and so much more.

For many companies, the ability to receive advanced shipping notifications is now a prerequisite. IAOAI WMS allows for the scanning of serial shipment container codes (SSCC), enabling the supply chain to be tracked at far greater levels of detail. For example, you can process receipts simply by scanning a SSCC off the back of a trailer – it will then instantly be added to your system.

Not all suppliers have access to EDI and ASNs, but anyone can use a spreadsheet. As a result, where advanced receiving processes are not available from your supplier, you can ask them to pre-populate a spreadsheet, which can then be imported directly into the system. In this way, you can enjoy the benefits of advanced receiving processes for all suppliers, without exception.

Expected Receipts

The IAOAI WMS expected receipt function allows you to manage inbound logistics, providing an overall view of all expected receipts while giving you a clear idea of the resources required for unloading, processing, and putaway.

With the pre-advised delivery management system, you can import electronic messages from suppliers to give confirmation of products and quantities that are due to be delivered into the warehouse. Once the delivery arrives, the products can then be quickly and efficiently received into the warehouse and put away, updating and verifying the pre-advised delivery. This streamlines the goods in process while minimising the amount of resources required overall.

IAOAI WMS provides an immediate visual indication of the resources required. Before goods arrive in the warehouse, the degree of effort required to physically unload, process, and put away the stock is accurately displayed in a simple graphical format.

The goods in diary is an interactive ‘drag and drop’ feature that lets you view, add, amend, block, cancel, assign docking bay, and complete delivery bookings in calendar format for goods inwards deliveries. It also offers the ability to control repeat bookings.

Capturing item attributes through IAOAI WMS ensures that the quality of information provided to the professionals in your business is both timely and correct.

IAOAI WMS also offers various stock management and quarantine functions. For example, you can auto freeze inbound stock to prevent any order commitments prior to technical sign-off. This process transfers the ownership of the task from the warehouse teams to the more appropriate technical areas of the business, ensuring stock is never sent out in error.

Returns Management

Returns happen, and you need to be able to process returned stock so that it does not interfere with the daily operation of your warehouse.

With intelligent identification, stock receipt, and relabelling, it allows for the efficient relocation of products using flexible rule based processes, saving you a huge amount of time and effort.

A good returns management system enables you to continue to offer a great service to your clients and customers long after the stock’s left your warehouse. Returns management software is therefore an essential part of any warehouse management system.

IAOAI WMS boosts your productivity while hugely reducing processing costs. The end result is a more efficient warehouse, and more satisfied clients and customers.

Full Quarantine and Release Functionality

You need to be able to quarantine stock so that it does not interfere with any of your other ongoing processes, enabling your warehouse to function more efficiently.

Luckily, there is an easy fix for this – and it comes as standard with IAOAI WMS.

Our stock quarantine management system automates the holding of your goods as early as possible – at the inbound receipt process. And because our system allows you to define a detailed profile for every item in your warehouse, you can even define which stock is to be frozen on an individual item-by-item basis.

There are many reasons why you might need to quarantine your stock. For instance, it might need to be temporarily held to allow your QA specialists to do their job, ensuring that your stock meets all the necessary criteria before it hits the markets.

In short stock situations, some businesses quarantine their stock to prevent their goods from being dispatched to the wrong customers. Finally, some warehouses quarantine their stock whilst the putaway task is in place. In this way, order lines and inbound receipts are never compromised by ongoing stock replenishment, which means that your supply chain is never disrupted, and your customers are always satisfied.

Efficient stock quarantine processes enable you to streamline your operations, ensuring that your products reach the market on time and fully compliant with all relevant regulations.

Optimal Put Away Control

Put-away processing is pivotal to ensuring that you are making best use of your available space, and that products are efficiently located to enable the most cost effective storage and retrieval. The multiple schemes available in IAOAI WMS allow both structured and flexible options, giving you a choice of processes that can be tailored to suit your unique product requirements.

The software makes use of cascade logic to change put away rules together, allowing for the best possible put away planning. For example, the ability to store allergens well away from any contaminants is a vital requirement in any food warehouse. IAOAI WMS can take care of that, with ease.

Like all IAOAI WMS transactions, the putaway process in the warehouse is tracked and traced at a high level of detail to ensure optimum performance. Any non-conformance to original putaway instructions is logged automatically, so you can easily identify any potential problems before they are allowed to escalate.

Replenishment Optimisation

Anyone who has spent any time in a warehouse will tell you that replenishing stock is not as easy as it looks.

To the untrained eye, it might seem as though it is as simple as moving stock from one place to another. But the truth is, if you replenish stock without a clearly-defined system in place, you run the risk of compromising order lines, disrupting your supply chain and, ultimately, letting down your customers.

IAOAI WMS features a replenishment optimisation process to guarantee that stock is only ever moved from the most suitable location.

How does it work? It is simple – our system allows you to define a detailed profile for every item in your warehouse, which includes strict replenishment rules. With these rules in place, you can rest assured that your stock will be moved from the bulk location to the pick location without ever compromising your order lines.

This system is particularly useful in high volume facilities where the need to optimise pick face replenishment is particularly important.

IAOAI WMS lets you adopt whichever replenishment strategy works for you. You can even automate the generation of replenishment tasks based on current and pending demand using the wave generation process.

On top of this, our replenishment processor allows a typical minimum trigger level for the creation of a replenishment, so you’ll never miss out on a sale due to empty shelves.

As a last resort for those unplanned eventualities like unaccounted damages in the pick face your staff can still initiate the replenishment process themselves.

Perpetual Inventory Process

Perpetual inventory systems, or cyclical counting, is the daily process of verifying the on-hand quantity of a specific number of stock products.

The IAOAI WMS cyclical counting functionality significantly reduces the need for your business to produce complete stock counts on a monthly or yearly basis. Indeed, if a structured ABC count classification is adopted, it is possible to demonstrate the ability of the process to a point where these fixed and expensive counting procedures are no longer required at all.

Cyclical counting is the most effective method of accurately recording and maintaining the inventory in your warehouse. The process offers many advantages, including:

- The ability to continue working while counting is in process

- The accurate recording of all material movement

- Ensuring that stock receipts are put away in the correct location

- Preventing shrinkage from theft and the mishandling of stocked items

- Allowing the Audit trail to be shortened to a more acceptable level

- The opportunity to improve your processes through effectively analysing any stock discrepancies

Extensive QA Traceability

When product quality issues are raised, it is vital that affected products can be quickly and accurately identified throughout the entire supply chain. Audit routines provide a trail of what has happened to each unique element of stock during its entire lifecycle, providing extensive traceability options.

IAOAI WMS’s freeze stock process can see goods automatically frozen at product receipt if required.

Some items may need to be positively released on the back of test results. Where this is needed, the release of this stock can be processed in the quality departments easily, quickly, and most importantly, with a full audit trail.

From start to finish, IAOAI’s traceability software allows complete visibility of the process. What is more, the process is so simple and so flexible that it can easily be delegated to a more focused quality control team, giving your warehouse team more time to do what they do best.

Full User Authorisation

Task and Resource Management

Few people seem to appreciate just how complicated running a warehouse can be.

Firstly, there is the stock, it is all over the place, even the simplest of warehouses can host hundreds of different items of stock, and every single item will have its own unique shipping and storage requirements.

Then there is the processes. At any one time, Receiving, Picking, Packing, Replenishments, Perpetual inventory counts can all be taking place, and every single one of them can be said to be integral in its own way.

With all this going on, you need systems in place that can ensure that all of your available resources – including your trucks, your staff, and your supply chain – are being used to the best of their abilities at all times.

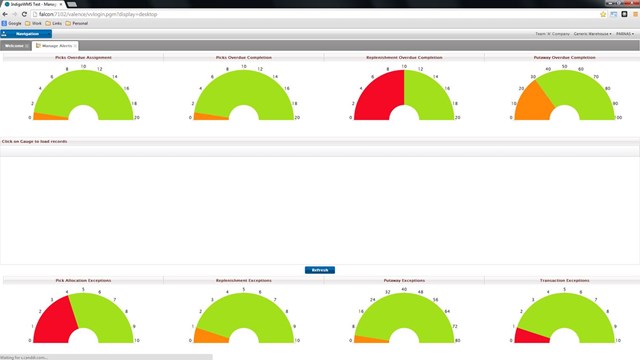

IAOAI WMS features a warehouse resource planning dashboard that gives you a full, uncluttered, and intuitive view of all of your ongoing processes. At a glance, you can see what everyone is doing, and act upon any potential issues long before they become problematic.

Our warehouse resource planning system lets you define your areas and your priorities, so you only ever see the information that’s relevant to you.

For example, the system can drive the picking of bulk pallets in the warehouse, letting you keep trucks in specific zones of the warehouse until all transactions have been processed. Full pallet and pick face demand can then be automatically assigned, by priority, to trucks in the warehouse based on their ability to work in those areas.

The system can also boost the efficiency of your staff through processing numerous transactions at once. Say, for instance, that one of your operators spends his shift moving full pallets from bulk locations to marshalling locations. But with the appropriate authorisation, this system can instead issue the occasional Replenishment or even Stock Counting transaction – whatever is needed to keep things running smoothly.

With IAOAI WMS, even the most sprawling and complicated of warehouses can be streamlined with ease.

Efficiency Reporting

Running a successful warehouse is an extremely complex business. At any given moment dozens of processes are taking place simultaneously, and each process is as critical as the next.

As a result, if something goes wrong – or if you feel that your warehouse is not performing quite as well as it should be – it can often be difficult to pinpoint the source of the problem.

That is where IAOAI WMS can help. With our efficiency reporting software, you can get a complete overview of how every process is performing, all in one single intuitive and uncluttered interface. IAOAI WMS is built around a structured relational database, providing all the data required to give you full visibility of the current work in progress, alongside a statistical analysis of all completed work.

An extensive catalogue of enquiries and reports gives you selected views of the warehouse performance at whatever level is required. Some transaction data is pre-cubed to allow efficient up to the minute reporting via the leading analytical tools, without having to process additional extract updates.

With the IAOAI WMS efficiency reporting tool, you will always know precisely what to do to ensure that your warehouse is operating at its best.

Best Practice Picking Strategies

Flexible picking strategies define the efficient warehouse. IAOAI WMS provides numerous picking styles ensuring that demand is always picked in the most efficient and appropriate manner.

Orders can be consolidated by customer, allowing an efficient pick path while removing any wasted time in the process. Waves of orders can be released based on the selected demand. Order priorities can be changed throughout the process to ensure the most important orders are picked in a timely manner. Integration via Application Programming Interfaces (APIs) allow external route scheduling applications to feed orders into IAOAI WMS.

The IAOAI WMS line picking process will support picking on a “just in time” basis. This can apply to products that are manufactured in batches, and for example we have seen this in the “food to go” sector, this could be an issue for any environment in which products are being manufactured in batches.

The principle is that the product, shelf life, and lot information are identified via scanning, then orders requiring the product are fulfilled in turn. The system can be configured so that the decision on which orders are satisfied first can be manual or automated, with the operator being presented with the next highest priority order.

The solution also introduces the capability to Top Off part picked orders, allowing pallets which have been mostly picked to be topped up with the remaining products, as the products enter the warehouse. This process leads with the identification of a pick list, then showing the outstanding products, which can be selected and instructions obtained.

Consignment Management

You have total control of almost everything that occurs within your warehouse. But when it comes to consignment inventory, there’s so much that’s out of your hands, so there’s so much that can go wrong.

The problem is, your end users have enough on their plate as it is without worrying about the particulars of storing and shipping your stock. This can be particularly problematic if you deal in controlled substances, high value goods, or the sort of perishables that require storing at a certain temperature.

But if you do not have access to item level information, how can you be sure that you are complying with all applicable regulations? How can you be sure that your consignment inventory isn’t standing on the shelf for weeks beyond its sell-by date? How can you be sure that you are not paying through the nose for unnecessary excessive storage and shipping costs?

IAOAI WMS provides a flexible approach to consignment management through allowing all of the most crucial decisions to be made at the most appropriate point in the fulfilment process. Meanwhile, management dashboards ensure that multiple shipping methods can be adopted in the most efficient and cost-effective manner possible.

Pallet and Load Assembly

Once picking is completed, there may be opportunities to re-prioritise or consolidate pallets of stock in the outbound loading bays prior to despatch. IAOAI WMS allows pallets or containers to be merged, deleted, and consolidated, allowing you to optimise loads and reduce transportation costs.

The ability to positively confirm that each pallet has been loaded onto a vehicle removes the final obstacle in the order picking process. All pallets must be positively confirmed as part of the loading process, which removes the risk of a pallet being left on the loading dock in error.

Voice Enablement

IAOAI’s voice WMS treats voice enabled users as simply another resource in the warehouse, driving picking events in the normal manner. Voice users can be mixed and matched with RDT operators, providing an ideal combination of optimised high speed picking processes, and more typical RDT based bulk pick transactions. And of course, hands-free voice-activated devices mean that your operators will no longer have to carry a mobile computer.

The IAOAI WMS Voice picking software is particularly useful in sub-zero warehouse operations, where the need to wear gloves to keep warm means that their removal can seriously impede the picking process using RDTs.

The benefits of using IAOAI’s Voice Picking Module are:

- Low cost and easy implementation

- Gives you full visibility of all picking based activity

- Improved productivity levels

- It is robust and easy to support

- Totally hands free

- Can be used in mixed mode (Hand held RDT’s and Voice devices)

- No interfaces to stand-alone voice systems

- No external professional services from multiple companies to implement

- No internal IT requirements to support separate systems

Some FAQ:

1. Can I use my existing warehouse RF network?

A. Provided your network is 802.11 compliant, it is likely you can use the existing network

2. Can it handle different dialects and accents?

A. Yes, each user trains the system for their own voice allowing the technology to accurately recognise any user’s speech.

Carrier Integration

More and more businesses have complex carrier requirements in which multiple carriers are deployed to obtain the most efficient mix. IAOAI WMS Parcel Courier Interface provides full integration with existing parcel couriers systems without the need to re-key any additional data.

Most carriers require the same details, including contact details, postcode, and opening times. However, the way in which data is transmitted and received varies. IAOAI WMS interfaces with host systems using a variety of file formats, including .csv .xml .txt.

When high volumes of shipments are being built, it is vital that the right documentation is sent to the right place to ensure the accuracy of operations and the efficient use of resources. IAOAI WMS allows document routing to be tailored to suit individual requirements of each shipment. You can therefore rest assured that all documentation will be delivered correctly, with no need to re-key any additional data.

Consignment Management

You have total control of almost everything that occurs within your warehouse. But when it comes to consignment inventory, there’s so much that’s out of your hands, so there’s so much that can go wrong.

The problem is, your end users have enough on their plate as it is without worrying about the particulars of storing and shipping your stock. This can be particularly problematic if you deal in controlled substances, high value goods, or the sort of perishables that require storing at a certain temperature.

But if you do not have access to item level information, how can you be sure that you are complying with all applicable regulations? How can you be sure that your consignment inventory isn’t standing on the shelf for weeks beyond its sell-by date? How can you be sure that you are not paying through the nose for unnecessary excessive storage and shipping costs?

IAOAI WMS provides a flexible approach to consignment management through allowing all of the most crucial decisions to be made at the most appropriate point in the fulfilment process. Meanwhile, management dashboards ensure that multiple shipping methods can be adopted in the most efficient and cost-effective manner possible.

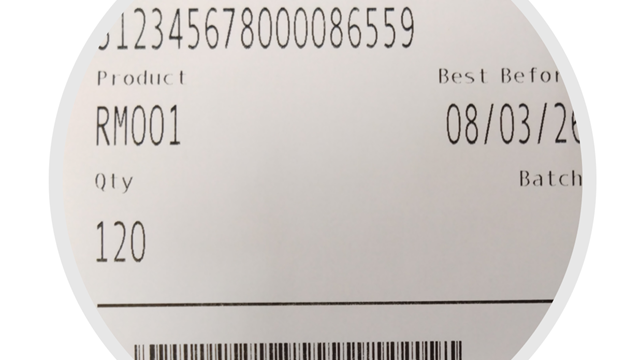

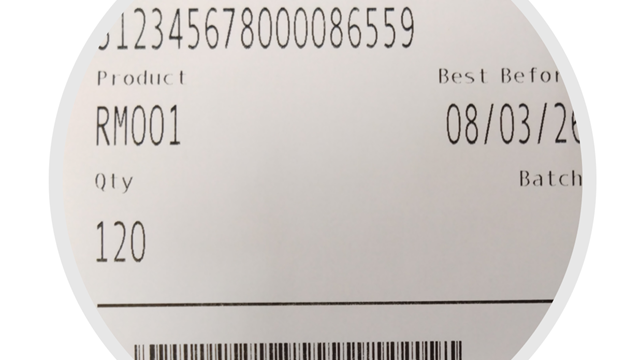

Industry Standard Labelling

Serial Shipping Container Codes (SSCC) are used to identify and trace logistic units, such as crates, cases, pallets, and parcels, throughout the storage or transportation process.

IAOAI WMS enables you to experience the benefits of SSCC control throughout the entire life cycle of stock within the warehouse. Outbound inventory can be identified with SSCC labels as originally received, applied during pick, or as part of the packing process.

Our SSCC label software cleverly allows disparate systems to share the same core supply chain data. For example, when you send products to customers, you can reuse the data on existing labels, making your stock traceability significantly more efficient, secure and reliable.

And of course, through linking your SSCC to additional information about your logistical units, such as advanced shipping notices, you can speed up the delivery and invoicing process, enabling both you and your clients to enjoy a more streamlined and efficient service overall.

Advanced Shipment Notifications

A warehouse is just one link in a much larger supply chain. This means that even the best-run warehouses can only ever be as efficient as the rest of the chain. If just one area is underperforming, then the entire process can grind to a halt.

But with a good warehouse management system (WMS), not only can you streamline your own operations, you can also do your bit to ensure that things are as good as they can possibly be even after your stock is dispatched.

IAOAI WMS lets you send advanced shipping notifications (ASN) to your trading partners at the time of dispatch.

Because they will be able to view all impending arrivals, your trading partners will be able to plan the receipt and ensure the process is effectively resourced. This will reduce the overall time taken to process shipping while ensuring that the accuracy and quality of their data is maintained.

ASNs can speed up the delivery and invoicing process, enabling both you and your clients to enjoy a more streamlined and efficient service overall. So IAOAI WMS will just improve your operations. It will improve the operations of everyone you deal with.